Boiler Rooms

Explore our solutions available for boiler room gas and water leak detection.

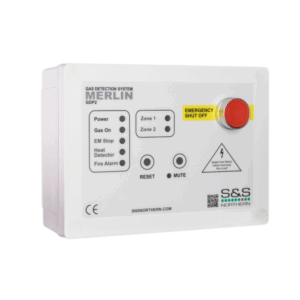

S&S Northern provides advanced gas detection and isolation systems engineered for complete boiler room safety and compliance. Our range includes gas detectors, solenoid valves, emergency shut-off buttons, CO interlocks, and zone monitoring panels with remote sensors for continuous detection of methane, CO, LPG, and other hazards.

Designed to meet the latest British Standards and IGEM regulations, our systems ensure reliable protection, early warning, and automatic shutdown in unsafe conditions. With thousands of installations worldwide, S&S Northern is the trusted choice for safe, compliant, and efficient boiler plant operations.

All products adhere to:

ISO9001

BB100

IGEM UP/2

BS6644

Full package solutions for boiler rooms

Frequently asked questions

What are the regulatory requirements for a boiler room gas safety system?

BS6644

A means of gas isolation must be incorporated at the entrance to the boiler room.

If it’s not practical to fit a manually operated valve, in an easily accessible position, then an electronic control valve can be fitted with an emergency knock-off button. (Such as the Merlin 500s with S&S Gas Solenoid Valve & Remote Emergency Stop).

BB100

Building Bulletin 100 is a document which discusses fire safety in educational establishments and explains the requirements for science laboratories, kitchens and school boiler rooms.

Building Bulletin 100 states that school plant rooms (where they are part of the main building) should be classed as a high fire risk and therefore recommends the following precautions –

- An emergency knock-off button should be installed at the entrance of the boiler room and connected up to the isolation valve so there is a way of isolating the gas supply in the event of a emergency.

- Heat detectors should be included over each boiler. If the boiler was ever to catch fire, the heat detector would automatically alarm and cause the gas solenoid valve to shut off.

- The gas solenoid valve can be automatically reset in the event of a power failure to reduce the risk of frozen pipework in cold periods, however in the event of a genuine alarm the system must be manually reset to restore the gas supply.

- Gas Detectors are recommended to be connected to a gas detection system, in the event where a gas is detected then this should cause the system to give out an audible alarm and shut off the fuel supply in the boiler room. The most common detectors used are carbon monoxide and natural gas. However, for LPG installations an LPG detector should be considered.

The detectors should be fitted at the following locations –

Natural Gas – 300mm from the ceiling

Carbon Monoxide – 1700mm from the floor

LPG – 300mm from the floor

Do I need to include gas detection in my boiler room?

Yes, gas detection is recommended in boiler rooms, especially in educational establishments as outlined in Building Bulletin 100 (BB101). Gas detectors should monitor for hazardous gases like methane, carbon monoxide, or LPG. If gas is detected, the system should trigger an audible alarm and automatically shut off the fuel supply to ensure safety.

Do I need to include remote emergency shut-off buttons?

Yes, an emergency shut off button should be installed at the entrance of the boiler room, as recommended by BB101 and BS6644. This button provides a quick way to isolate the gas supply in case of an emergency, enhancing safety and compliance.

Do I need gas pressure proving in my boiler room?

Gas pressure proving is not required in boiler rooms, however it is required if the boiler does not have flame failure devices and in educational establishments.

Are heat detectors (fusible links) required?

In educational establishments, yes. Heat detectors or fusible links are required above each boiler, as per BB101. These devices automatically shut off the gas supply if the temperature exceeds safe limits, preventing fires and enhancing safety.

In all other commercial & light industrial boiler rooms, heat detectors are installed as best industry practice and to further protect life & property.

What products are available from S&S northern Ltd?

S&S Northern’s boiler room gas detection and isolation systems are expertly engineered to provide comprehensive protection against hazardous gases such as methane, carbon monoxide, and LPG. As a leading supplier, we manufacture and supply advanced systems designed to enhance the safety and compliance of industrial and commercial boiler rooms.

Our high-precision gas detectors are designed to monitor gas levels continuously, offering real-time alerts for dangerous concentrations and enabling early intervention. Our product range includes critical ancillary components such as emergency stop buttons, which facilitate immediate gas supply shutdown in emergencies, and fusible links that automatically close the gas supply if temperatures exceed safe limits, safeguarding against overheating.

Additionally, we provide remote audible alarm beacons that notify personnel of gas detection events or system malfunctions from a distance, ensuring prompt awareness and action. Our selection of solenoid valves, including normally closed types, is crucial for effective gas control, automatically shutting off the supply when unsafe conditions are detected.

With thousands of installations globally, our systems are renowned for their reliability and compliance with the latest British Standards and IGEM regulations. Choose S&S Northern for high-quality, reliable gas detection and isolation products that support safe and efficient boiler room operations.